[kl-bogel] The production of oak barrels for cognac (37 photos)

Do not be afraid to call the magic of the transformation of a pure and clear as the morning dew, grape alcohol, just to cool off in the distillation coil, cube, dark amber liquid, filled with sunlight, warming the vineyards. As nothing but witchcraft could be called the process of changing the taste of alcohol with a pronounced fruity in aged cognac with untold variety and flavors of nutmeg and flowers, coffee beans and vanilla, fruit and chocolate. This is the magic of transformation presents us with a bouquet of aromas and long finish changing cognac, something for which he is loved and appreciated.

Procedures and technology of cognac rigidly defined and strictly regulated. Oak for barrels had to grow up in France. In the production of these barrels cooperage oak is used in two French regions: Limousin and Tronse.

We sergeydolya dima_chatrov and passed along the entire process of manufacturing oak barrels for cognac in the world's largest cooperage industry - factory Seguin Moreau.

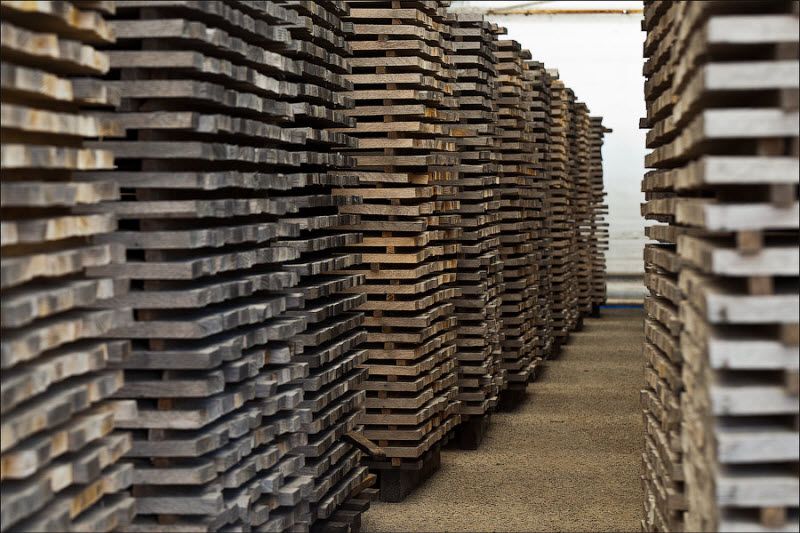

The cut sandwiches as oak barrels dried for eight months in the wild

Then napilivayutsya not identical plaques, which will be collected from a barrel. These tablets are dried for approximately 3-4 months. The surface of the wood darkens

Using the technology of drying boards occasionally watered

dima_chatrov taste the oak juice, trying to determine the flavor characteristics of the future of brandy

All pieces of wood carefully sorted for marriage and defects. All storage areas are labeled

After drying, the blanks shaved and the process of assembly. First collected by one side of a metal drum hoop

The resulting half-barrel is placed on a brazier for burning the inside surface. Fire softens the surface of the oak, and as a result of thermal treatment of glucose contained in the wood structure, a layer of sugar.

The degree of roasting significantly affect the taste of cognac.

Collected in the bottom of the barrel hoop

Barrel rolls and re-fired

Finally, tightly contracted fixing hoops

Polished

Bottoms installed

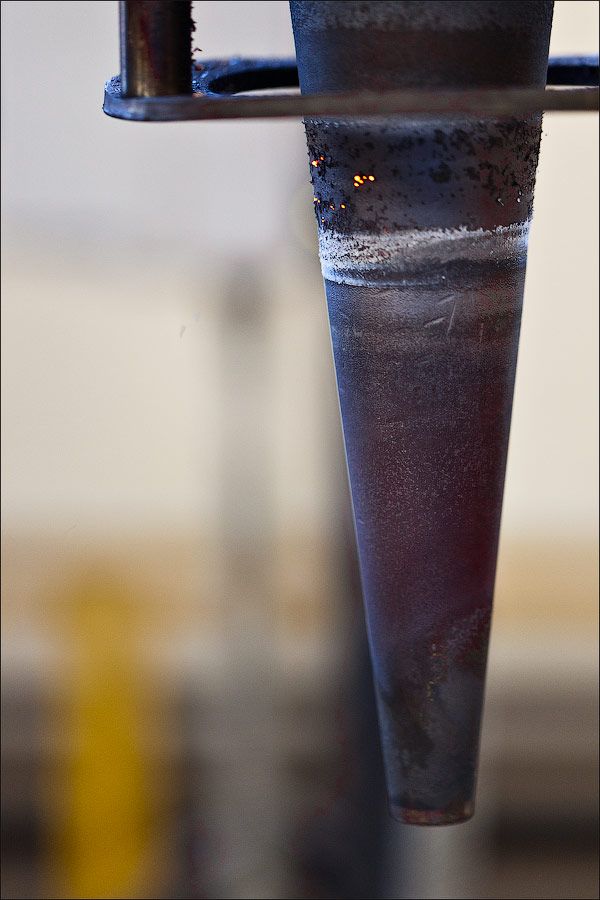

Warmly heated tip burnt a hole in aspic

Its tapered shape and size is fixed

The barrel is equipped with a stopper

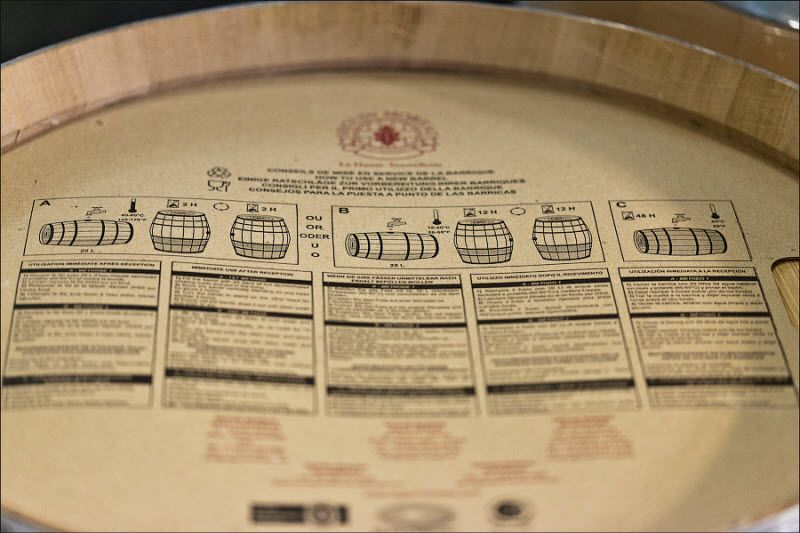

Instructions for use

Glued pride

And the barrel goes into the finished product storage

In a separate workshop gathered a huge barrel of wine

Source: kukuksumushu.livejournal.com

You received this message because you are subscribed to the Google Groups "kl-bogel" group.

To post to this group, send email to kl-bogel@googlegroups.com

To subscribe or unsubscribe at http://groups.google.com.my/group/kl-bogel/subscribe

For more options, visit this group at http://groups.google.com/group/kl-bogel?hl=en

Sebarang email pertanyaan, hantar kepada abangmod@gmail.com

Comments

Post a Comment